Challenge

Unilever, a leading multinational consumer goods company, asked Premise to help them understand a segment of their supply chain into which they had little visibility: the first mile of their palm fruit production in Indonesia. Palm oil is a key ingredient in nearly half the world’s packaged goods, but its production is notoriously rife with environmental abuse. Committed to supply chain accountability, Unilever needed to shed light on the practices, locations, and logistics of their palm fruit suppliers.

Solution

Premise enlisted a specially-trained subset of its Contributor network in the region to photograph and record palm fruit pickup locations, and to provide subjective insights into those locations.

To map how the product traveled from tree to mill, Contributors were asked the following questions:

- Where are these palm fruit collection sites located?

- What did these palm fruit pick-up points look like? What equipment or infrastructure did they have?

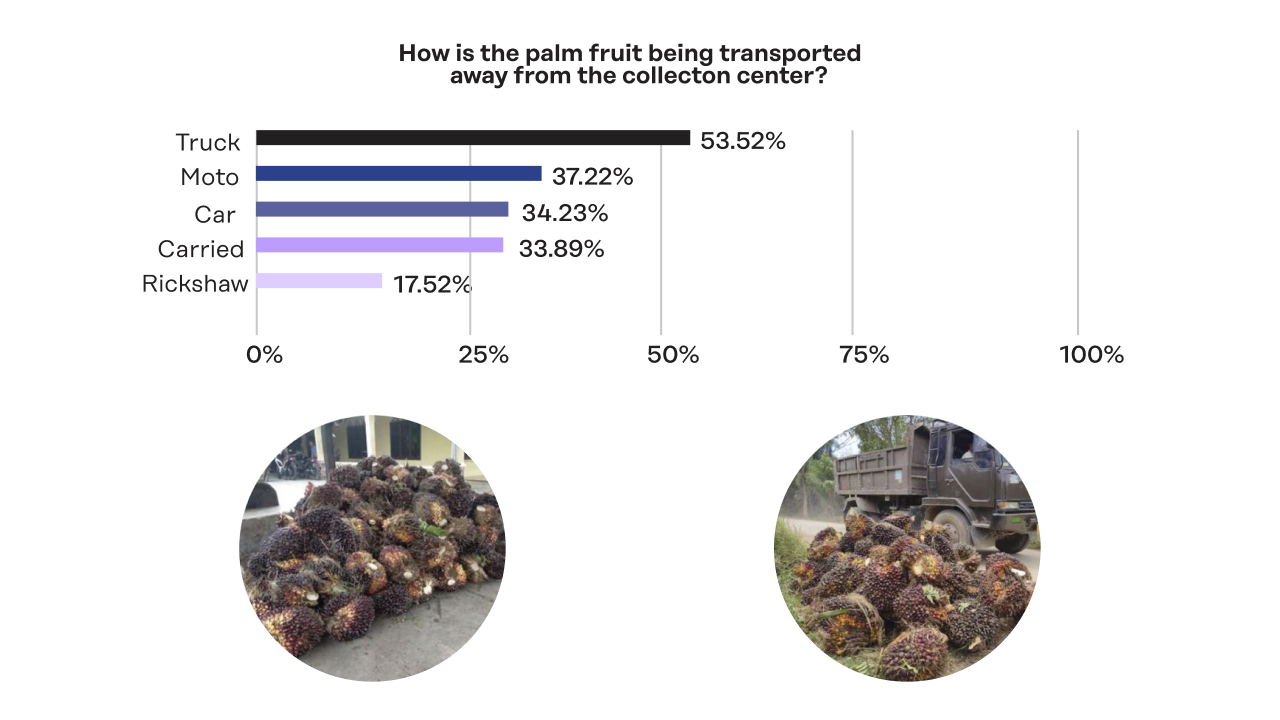

- What days and times did the palm fruit get picked up and how was it transported away?

- How much did the raw palm fruit cost at these collection points?

Within a few months, Premise Contributors mapped thousands of individual palm collection points across the region, with each location accompanied by qualitative observations and photographs.

Findings

Premise Contributors documented previously unseen types of pick-up sites, which Unilever was able to use to update their operations directory. The findings exposed inaccuracies in the client’s assumptions around the size, distribution, and complexity of the palm fruit supply chain. Small, informal pick-up spots with little or no infrastructure were significantly more common than previously thought. In fact, these sites were discovered to supply the majority of the fruit to surrounding mills.

Additionally, Unilever learned through Premise that there was a coordinated approach among local drivers to collect the palm fruit on dedicated days, in certain areas, within the region.

Finally, the price was found to fluctuate more over time than between pickup locations, suggesting that the size of the pick-up site had less impact on the price than previously believed.

Implications

Equipped with these observations from Premise, Unilever was able to:

- Learn the location of palm fruit pick-up sites, their distance from processing mills, and travel times throughout the supply chain’s first mile

- Gain insight into the distribution and frequency of palm fruit collection points and the resulting effect on pricing

- Become more transparent and data-driven in their commitment to creating sustainable supply chains